So this was about as easy as I thought it would be. I must be getting better.

These jacks are well known for loosening up and not making good contact with the guitar cable.

Sure, it'd be easiest to just replace with new ones of the same kind, but you'll only be replacing

them again at some point in the not too distant future.

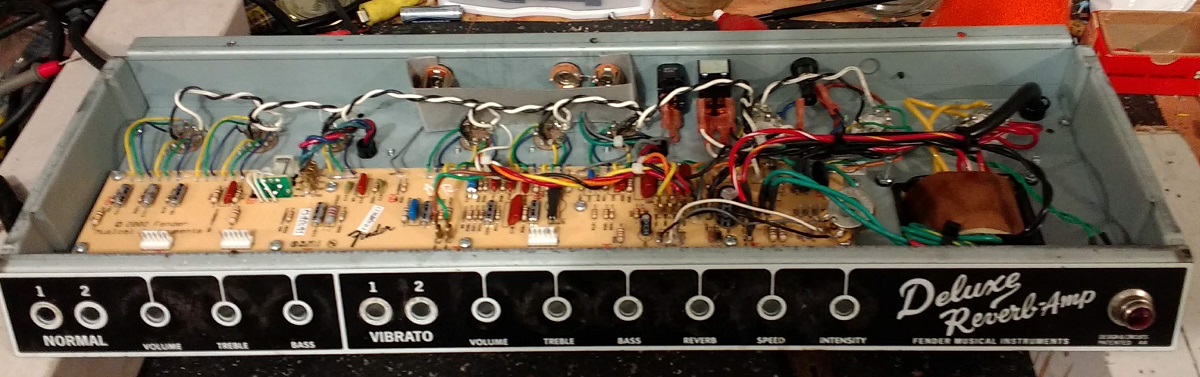

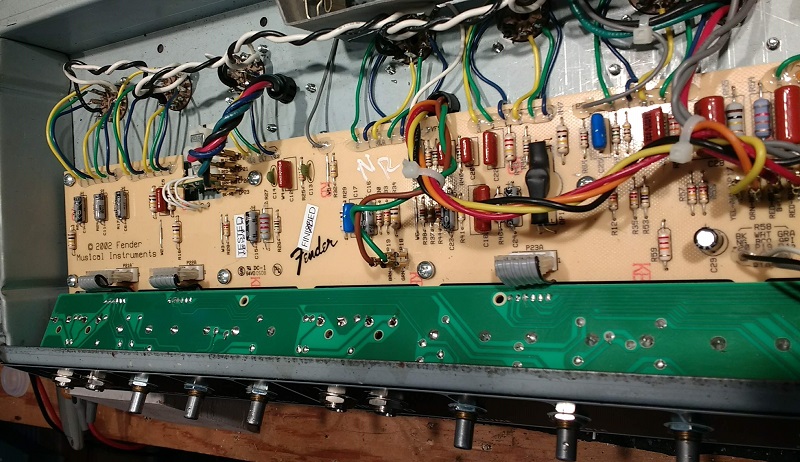

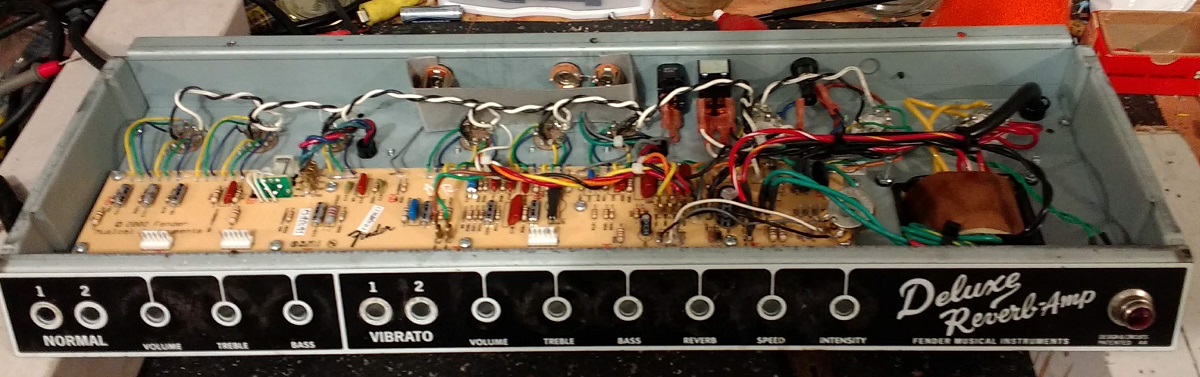

I pulled the chassis from the amp cabinet and opened it up. Some gratuitous "gut shots" follow.

This was the first time I actually had my hands on a Fender amp of any kind for repair.

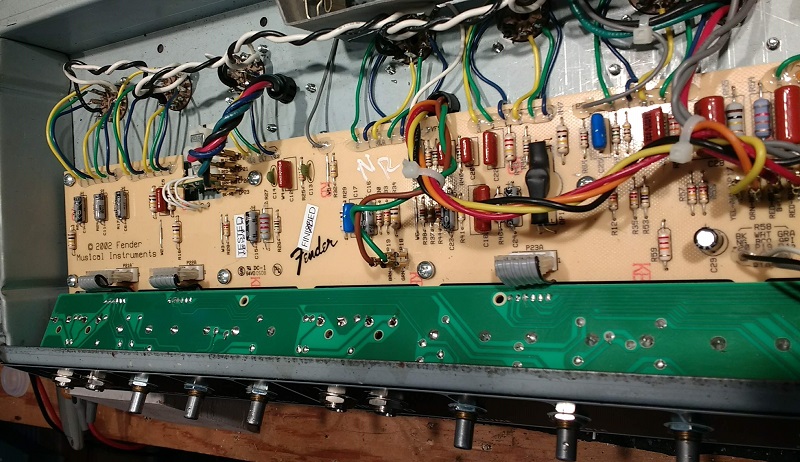

Unsoldering and removing the existing jacks was easy. Fender uses good quality circuit boards in comparison

to some other ones I've messed with in cheaper stuff. And the solder was good ol' 63/37!

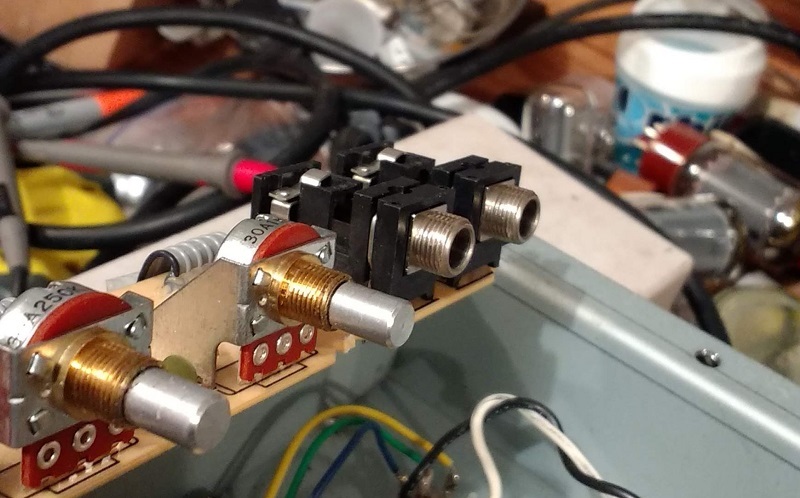

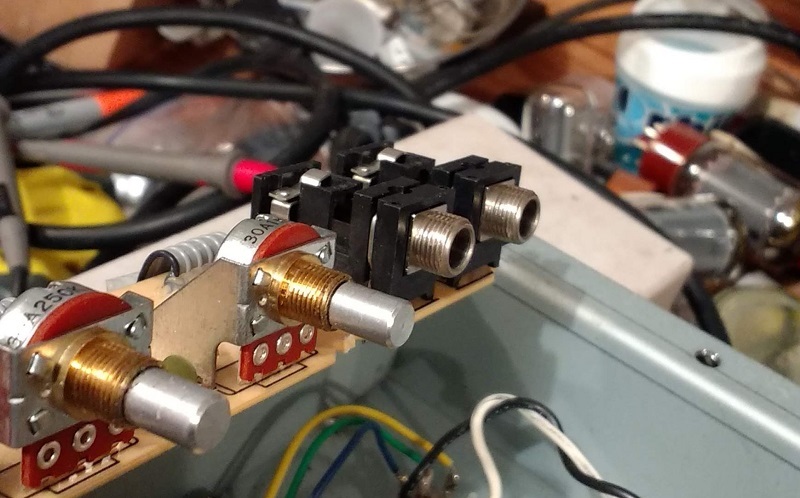

I ran short 1.5" jumper wires from the Switchcraft jacks to the board. I left enough bend in the wire

so there wouldn't be strain on anything when I mounted them to the panel. The first jack I did (far left)

I used 20 gage wire and it was a little stiffer than I wanted, so the other 3 got 22 gage.

I left the 20 gage in place, since any circuit board will only take so much heat before the pads

start lifting off.

Tucked back in and everything fastened down. I put a small bend in the wire where it goes through the

hole in the board, and soldered lightly. The holes are way bigger than the wire, so there was no point

trying to fill the entire hole with solder just for appearance's sake. The less heat, the better in my opinion.

And all buttoned up and ready to rock! It looks like the amp tech was resting his sandal on the top of the amp

while testing it. But, I'm sure that didn't actually happen!